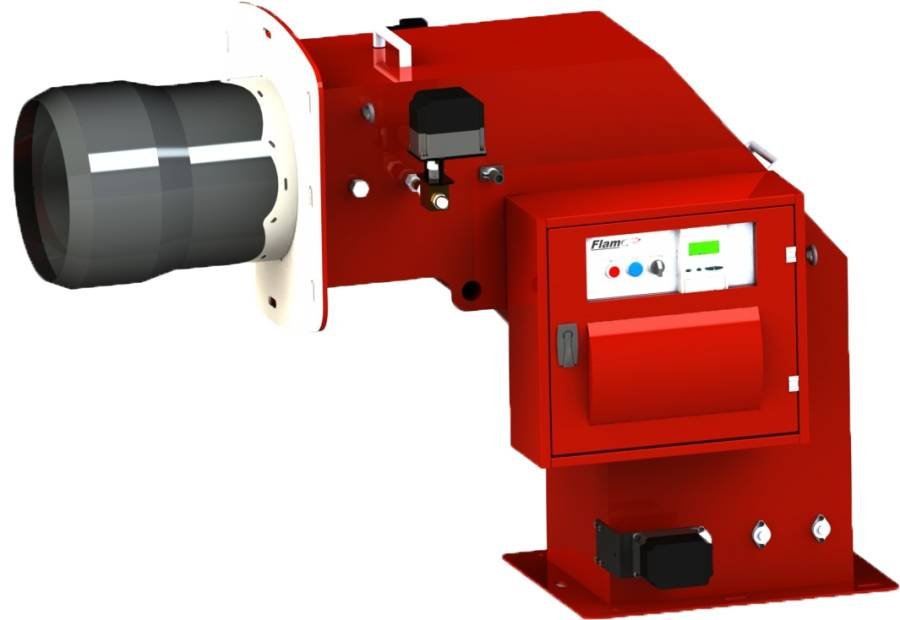

Gas /Heavy oil electronic modulation Duobloc Burner

Ürünler

Kapasite min. kw

Kapasite max. kw

SC 16.1 GHM Gas /Heavy oil electronic modulation Duobloc Burner

2600

10500

SC 16.1 GHM Gas /Heavy oil electronic modulation Duobloc Burner

Technical information

SC. 16.1 GHM | |||||

|---|---|---|---|---|---|

| Capacity | Kw/h | Min | 2600 | ||

| Max | 10.500 | ||||

| kcal/h | Min | 2.236.000 | |||

| Max | 9.030.000 | ||||

l/h | Min | 232 | |||

| Max | 940 | ||||

| Power Supply | 3N-50 Hz 380V | ||||

| Gas Input Pressure | 21-300 | ||||

More information

1. Natural gas, propane, biogas can be used.

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

SC 16.2 GHM Gas /Heavy oil electronic modulation Duobloc Burner

3200

12500

SC 16.2 GHM Gas /Heavy oil electronic modulation Duobloc Burner

Technical information

SC. 16.2 GHM | |||||

|---|---|---|---|---|---|

| Capacity | Kw/h | Min | 3200 | ||

| Max | 12.500 | ||||

| kcal/h | Min | 2.752.000 | |||

| Max | 10.750.000 | ||||

l/h | Min | 286 | |||

| Max | 1119 | ||||

| Power Supply | 3N-50 Hz 380V | ||||

| Gas Input Pressure | 21-300 | ||||

More information

1. Natural gas, propane, biogas can be used.

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

SC 18.1 GHM Gas /Heavy oil electronic modulation Duobloc Burner

3450

14000

SC 18.1 GHM Gas /Heavy oil electronic modulation Duobloc Burner

Technical information

SC. 18.1 GHM | |||||

|---|---|---|---|---|---|

| Capacity | Kw/h | Min | 3450 | ||

| Max | 14.000 | ||||

| kcal/h | Min | 2.967.000 | |||

| Max | 12.040.000 | ||||

l/h | Min | 309 | |||

| Max | 1254 | ||||

| Power Supply | 3N-50 Hz 380V | ||||

| Gas Input Pressure | 21-300 | ||||

More information

1. Natural gas, propane, biogas can be used.

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

SC 18.2 GHM Gas /Heavy oil electronic modulation Duobloc Burner

3800

17800

SC 18.2 GHM Gas /Heavy oil electronic modulation Duobloc Burner

Technical information

SC. 18.2 GHM | |||||

|---|---|---|---|---|---|

| Capacity | Kw/h | Min | 3800 | ||

| Max | 17.800 | ||||

| kcal/h | Min | 3.268.000 | |||

| Max | 15.308.000 | ||||

l/h | Min | 340 | |||

| Max | 1594 | ||||

| Power Supply | 3N-50 Hz 380V | ||||

| Gas Input Pressure | 21-300 | ||||

More information

1. Natural gas, propane, biogas can be used.

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

SC 20.1 GHM Gas /Heavy oil electronic modulation Duobloc Burner

4400

22000

SC 20.1 GHM Gas /Heavy oil electronic modulation Duobloc Burner

Technical information

SC. 20.1 GHM | |||||

|---|---|---|---|---|---|

| Capacity | Kw/h | Min | 4400 | ||

| Max | 22.000 | ||||

| kcal/h | Min | 3.784.000 | |||

| Max | 18.920.000 | ||||

l/h | Min | 394 | |||

| Max | 1970 | ||||

| Power Supply | 3N-50 Hz 380V | ||||

| Gas Input Pressure | 21-300 | ||||

More information

1. Natural gas, propane, biogas can be used.

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

SC 20.2 GHM Gas /Heavy oil electronic modulation Duobloc Burner

5200

26000

SC 20.2 GHM Gas /Heavy oil electronic modulation Duobloc Burner

Technical information

SC. 20.2 GHM | |||||

|---|---|---|---|---|---|

| Capacity | Kw/h | Min | 5200 | ||

| Max | 26.000 | ||||

| kcal/h | Min | 4.472.000 | |||

| Max | 22.360.000 | ||||

l/h | Min | 465 | |||

| Max | 2329 | ||||

| Power Supply | 3N-50 Hz 380V | ||||

| Gas Input Pressure | 21-300 | ||||

More information

1. Natural gas, propane, biogas can be used.

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

SC 22.1 GHM Gas /Heavy oil electronic modulation Duobloc Burner

6000

30000

SC 22.1 GHM Gas /Heavy oil electronic modulation Duobloc Burner

Technical information

SC. 22.1 GHM | |||||

|---|---|---|---|---|---|

| Capacity | Kw/h | Min | 6000 | ||

| Max | 30.000 | ||||

| kcal/h | Min | 5.160.000 | |||

| Max | 25.800.000 | ||||

l/h | Min | 537 | |||

| Max | 2687 | ||||

| Power Supply | 3N-50 Hz 380V | ||||

| Gas Input Pressure | 21-300 | ||||

More information

1. Natural gas, propane, biogas can be used.

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

SC 22.2 GHM Gas /Heavy oil electronic modulation Duobloc Burner

7000

35000

SC 22.2 GHM Gas /Heavy oil electronic modulation Duobloc Burner

Technical information

SC. 22.2 GHM | |||||

|---|---|---|---|---|---|

| Capacity | Kw/h | Min | 7000 | ||

| Max | 35.000 | ||||

| kcal/h | Min | 6.020.000 | |||

| Max | 30.100.000 | ||||

l/h | Min | 627 | |||

| Max | 3135 | ||||

| Power Supply | 3N-50 Hz 380V | ||||

| Gas Input Pressure | 21-300 | ||||

More information

1. Natural gas, propane, biogas can be used.

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system

Heavy fuel, viscosity 50°E at 50 ° C, PCI 10,97 kWh / kg

2. It is suitable for steam, hot water boiler, ovens, driers, heat oil generators, etc.

3. The flame can be adjusted according to the combustion chamber.

4. Burning hood, ventilation system, control panel, gas pipe could be selected according to special conditions of each installation.

5. The 1/ 10 regulation of the electronic modulation power, is really advantageous compared to our rivals.

6. Flame monitoring is easy and reliable thanks to the UV sensor.

7. A customized type of sensor is used for sequentially installment of several generators.

8. The facility of heating and the use of preheated combustion air while enabling energy saving in increasing the efficiency of the burning through economiser used by the system.

9. It enables flame control at each point between minimum and maximum power. It enables flame control at each point between minimum and maximum power.

10. It has the characteristics of proper functioning in different combustion chambers.

11. Reduces the specific emission amount of nitric oxide (NOx) gas to a minimum by obtaining an optimum mixture of combustible air thanks to the customized design of its combustion hood.

12. It provides easy installation and operating conditions in confined spaces thanks to its compact dimensions.

13. It enables operation in high backpressure combustion chambers by placing a high-pressure ventilation system.

14. Ease of installation of the gas train to the burner.

15. Standard protection of IP 54 mechanical parts.

16. IP 65 protection on demand.

17. Internal or external optional circulation of combustion gases in order to reduce NOx emissions.

18. It includes all the cables and power supply of the burner management system.

19. Includes impermeability control.

20. Compliance with the following directives:

89/336(2004/108)EEC

73/23/EEC

98/37/EEC

EN 676

21. Continuous O2 analyzer in order to sustain extra efficiency.

22. Continuous CO analyzer for precise control system.

23. Speed variant to extend product life cycle.

24. Sound insulated ventilation system